Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

"Cutting-Edge Comedy: When Alumina Ceramic Meets Laser, Expect Hilarious Sparks!"

Model No.: Al2O3 412

Brand: Hard

Type: Plate

Material: Alumina Ceramic

Style: Western

Usage: Home Decoration

Feature: Chinese

Processing: Casting

Color: White/Ivory

Shape: Round

Age: Modern

Surface Decoration: Glazed

Application: Machinery, Industry, Medical, Aerospace Etc.

Packaging: Customized

Transportation: Ocean,Land,Air

Place of Origin: Guangdong,China

Supply Ability: 1,000,000 pcs/Month

Certificate: SGS

Port: Shenzhen

Payment Type: L/C,T/T,D/P,Paypal,Money Gram,Western Union

Incoterm: FOB

Introducing our "Laser-Whiz 3000" Alumina Ceramic Cutting Sheet Disc - the ultimate tool for slicing through any material like a hot knife through butter! Made with 95-96% alumina ceramic, this disc is tougher than your grandma's secret beef jerky recipe. It's so precise that it can even split a hair into two fashionable bangs! Whether you need to carve up steel, wood, or your annoying neighbor's unsightly garden gnomes, the Laser-Whiz 3000 has got your back. It's like having a superhero sidekick, but without the spandex and capes (unless that's your thing). So, say goodbye to frustration and hello to laser precision with our Alumina Ceramic Cutting Sheet Disc. Warning: May cause uncontrollable laughter while demolishing your DIY projects!

technical 95 96 Alumina Ceramic laser cutting sheet disc

Reputation depends on quality, quality comes from Hard!

Alumina ceramics, often referred to as the stainless steel equivalent in the ceramic world, exhibit remarkable resistance to weak corrosive environments like air, steam, and water. The Alumina Ceramic Disc stands as a testament to the superior properties of alumina ceramics, offering unparalleled performance and longevity in a variety of applications where corrosion resistance and strength are paramount.A lumina ceramics is the abbreviation of stainless and acid-resistant steel. Steels that are resistant to weak corrosive media such as air, steam, and water or are stainless steel are called stainless steel; and chemically resistant media (acid, alkali, salt and other chemical attack) The corroded steel is called acid-resistant steel. Due to the difference in chemical composition between the two, their corrosion resistance is different. Ordinary stainless steel is generally not resistant to chemical media corrosion, while acid-resistant steel is generally non-corrosive. The term "stainless steel" not only refers to a single type of stainless steel, but also refers to more than one hundred industrial stainless steels. Each stainless steel developed has good performance in its specific application field. The key to success is to understand the purpose first, and then determine the correct steel grade. There are usually only six steel grades related to the application of building construction. They all contain 17-22% chromium, and better steel grades also contain nickel. The addition of molybdenum can further improve the atmospheric corrosion, especially the corrosion resistance of chloride-containing atmosphere. Generally speaking, the hardness of stainless steel is higher than that of aluminum alloy, and the cost of stainless steel is higher than that of aluminum alloy. The invention and use of stainless steel dates back to the First World War. British scientist Henry Brearley was commissioned by the British government military arsenal to study the improvement of weapons. At that time, the barrel of the rifle used by soldiers was very easy to wear, and Brearley wanted to invent an alloy steel that was not easy to wear. The stainless steel invented by Blairley obtained a British patent in 1916 and began mass production. Since then, the stainless steel accidentally found in the garbage dump has become popular all over the world, and Henry Blairley is also known as the "father of stainless steel." During the First World War, British guns on the battlefield were always transported back to the rear because the barrel was worn out. The military production department ordered Blairley to develop high-strength wear-resistant alloy steel, specifically researching and solving the problem of gun bore wear. Blairley and his assistants collected various types of steel and alloy steels of different properties produced at home and abroad, conducted performance experiments on machines of various properties, and then selected more suitable steels to make guns.

High hardness, high strength, wear resistance, corrosion resistance, high temperacture (1600°), good thermal diffusivity, good insulativity, low cost etc.

Data Sheet↓

Color: White/IvoryThermal Shock Resistance: 200 △T°C

Maximum use temperature 1650°C

Dielectric Strength: >10 KV/mm

Dielectric Constant: 9.1er

Dielectric Loss Angle(1MHz): 0.0002-0.0003

Volume Resistivity(20°C): >1014Ω.cm

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

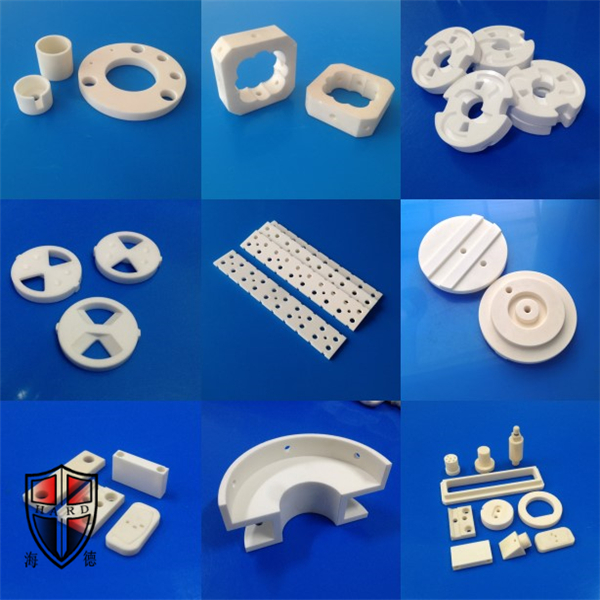

Products Show

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

Product Categories : Alumina Ceramics > Alumina Ceramic Disc

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.